About Us

FNJIA Apparel Factory was founded in 2005, integrating development, design, production, sales and service. It has its own design team, quality control dept., sales dept. and after-sales service dept.. Our main products are all kinds of sweaters, hoodies, T-shirts, dresses and yoga wear.

Our goal is to expand our business globally and become a leader in the clothing industry.

We are experts in large-scale apparel manufacturing, with over 18 years of expertise. We handle the whole supply chain process, from sourcing fabrics and accessories to producing samples, brand development by adding logos, bulk garment production, packaging, quality control inspections, and product delivery.

Here at FNJIA Apparel Factory, we have a whole team of experts who will take care of your every clothing production need, no matter how big or small the project is. Plus, our factory is based in China- so you can be sure that all of our products are made with only the best materials and craftsmanship! We prioritize quality and customer satisfaction above all else, treating each project as a partnership. This way, we can ensure that your vision comes to life exactly as you imagined it.

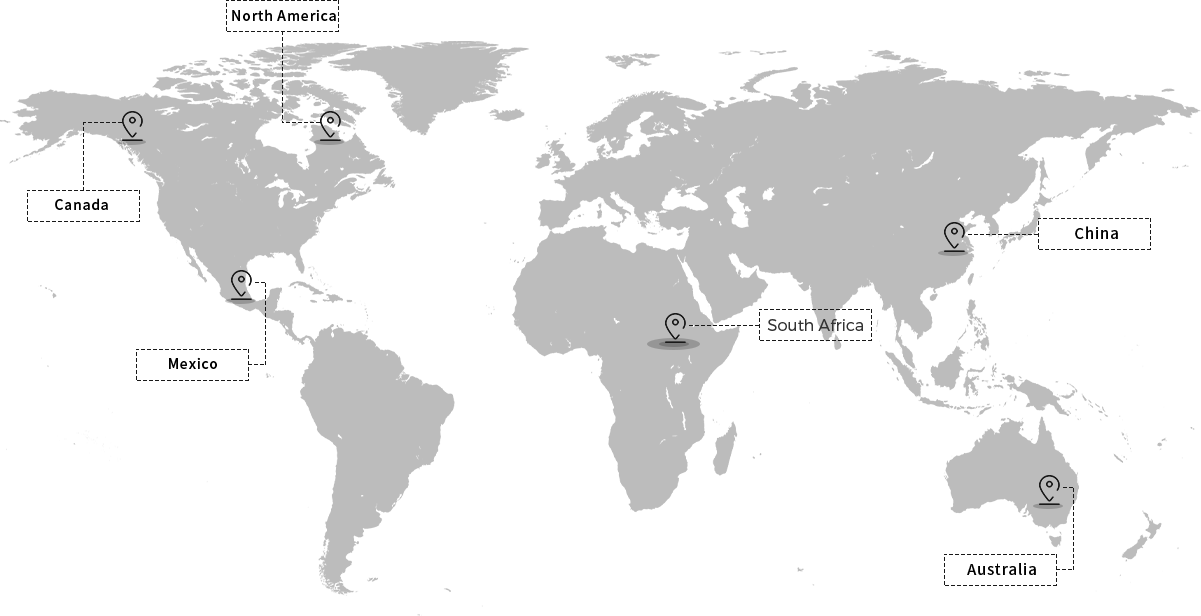

We wholeheartedly believe that with our assistance, any individual with creative ideas has the ability to establish their own fashion brand. To date, we have had the privilege of helping customers based all around the globe to launch and grow their fashion businesses and brands.

01

19+

Years of OEM experience in clothing industry

4153+

Stylish designs

100,000+

Monthly production Capacity

Quality Control

The quality control process at FNJIA Apparel Factory ensures that each garment meets high standards before it reaches the customer. Here's an overview of our quality control process:

02

Cooperative Partner

03

Why Choose US

04

01 Comprehensive Services

We offer a full range of services from development and design to production, sales, and after-sales service, covering all aspects of apparel manufacturing.

02 Expertise

With over 18 years of experience, we are experts in large-scale apparel manufacturing, handling the entire supply chain process with proficiency.

03 Quality Assurance

We prioritize quality and customer satisfaction above all else, ensuring that each project is treated as a partnership and delivering products made with only the best materials and craftsmanship.

04 Global Reach

Based in China, we have a global presence, serving customers from around the world and helping them launch and grow their fashion brands.

05 Empowerment

We believe in empowering individuals with creative ideas to establish their own fashion brands, providing the expertise and support needed to bring their visions to life.

Custom Your Own Design

We have a team of professionals who will turn your design into reality. With our expertise, you can be assured that each product meets the highest standards for quality and craftsmanship while still maintaining an affordable price point.

One-stop Solutions

FNJIA Clothes Maker is the perfect solution for all your garment and clothing manufacturing needs. From sample development and bulk production to label printing, delivery of goods — the experts at this factory will take care every step along with you!

We offer wide range of products such as women's dresses or men's shirts, sportswear and swimwear — there are many styles available which means that whatever kind clothing design you required, we can easily made it.

Environmental Protection of Materials

We have our own yarn and can also customize the environmental friendly yarn. We highly supervise the production of the yarn to real products.

Sustainable Development Concept

These recycled fabrics help reduce waste, conserve resources, and minimize the environmental footprint of clothing production, making them an eco-friendly choice for sustainable fashion brands and conscious consumers.

05